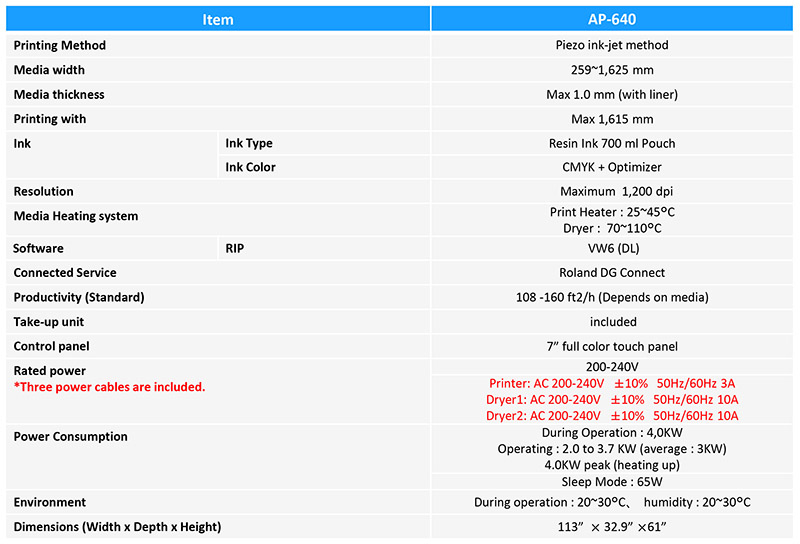

The AP-640 is an advanced resin ink printer giving customers an additional choice to meet the ever-changing demands of the print service providers. The new AP-640 combines all the quick-drying, environmentally friendly qualities of resin printing with

the amazing color, ease of use, and reliability that users have come to expect from Roland TrueVIS Series printers.

The AP-640 includes a 7-inch LCD Touchscreen Control Panel that allows users to intuitively access media setup and

other menu options with ease. Nozzle check and automated calibration features can also be accessed using the touchscreen. Use custom settings for each media with simple access at startup, including all calibration settings and media remaining amount. Easily operate the take-up system from the home screen and get a real-time view on

print heater, external dryer, and job remaining print times

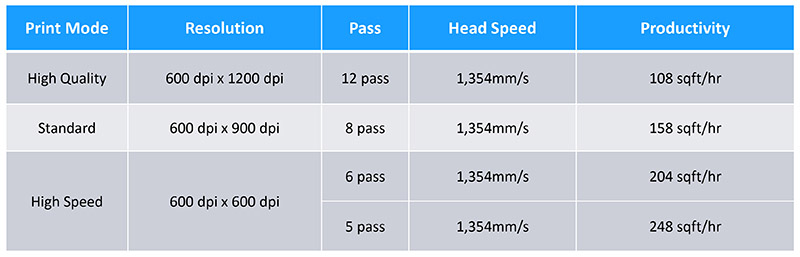

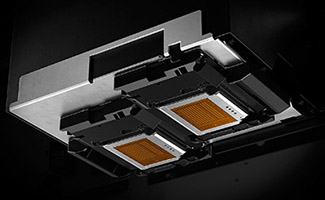

An all new dual piezo printhead design provides a platform for production-level speeds, while maintaining the output

quality needed to be competitive in today’s PSP market. Staggering the optimizer channels to the front of the print carriage helps to balance media stability and print quality without sacrificing throughput. TA Optimizer is jetted first with CMYK printing on top of the optimizer. The optimizer allows each ink droplet to form a fine dot on the media being printed. This method results in amazing color and print quality on a wide variety of media.

One of the innovative features added into the newly designed control panel is the ability to execute the media gap adjustment (also known as bi-directional and unidirectional adjustments).

In addition, the feed calibration adjustment can be printed, scanned, and corrected for accuracy in the same operation. This is a great time-saver for making finely tuned adjustments when changing out media from one application to the next. The user can simply walk away while the printer does the work.

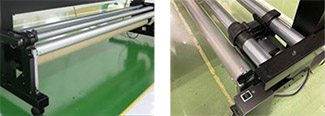

The TU4-64 automatic take-up system is designed to accommodate a variety of media widths. Tension mode provides incredible media stability when printing roll-to-roll applications.

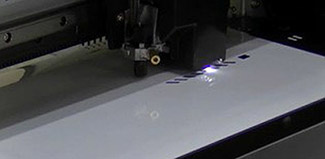

Designed specifically for TA Resin Inks, the AP-640 includes a robust drying system. This system has been engineered for simple installation, and heat settings are easy to control using the 7-inch LCD touchscreen. Profiles downloaded from the Roland Profile Center have predefined dryer settings for ease of use, while also allowing real-time control for any adjustments required due to environmental conditions. The system reduces post-production time and improves overall productivity, allowing the user to deliver applications to the market without delay.

TrueVIS TA Resin Ink is formulated to produce the rich, vibrant, natural color that the TrueVIS Series is known for. The new resin ink system uses CMYK in combination with “TA-OP” optimizer, allowing for high-quality prints on a wide variety of substrates with production-level throughput.

In addition to production-level throughput, TA inks are cured, dry and ready for application immediately after printing. With prints ready to apply directly off the printer, turnaround time can be reduced dramatically. Users will save time on post-production activity like outgassing prior to lamination.

High-capacity 700 ml pouches are perfect for high-volume applications such as banners, interior décor, and commercial vehicle wraps.