The BN-20 packs everything into one, powerful, profit-producing package. With award-winning eco-solvent inks including metallic and white options, a range of material compatibility and integrated contour cutting, the BN-20 is easily the most versatile print device in its class. The BN-20 is perfect for creating t-shirt graphics, poster prints, stickers and decals – all from the comfort of your desktop.

Roland Eco-Sol MAX ink offers fast drying time, high density, a wide colour gamut, rugged scratch resistance, a low cost per square foot and broad media support. The BN-20 can be set up in for printing both standard and luxury items. ECO-SOL MAX inks are GREENGUARD Gold certified, to meet some of the world's most rigorous standards for use in schools and healthcare environments.

All functionality of the BN-20 is handled through the included Roland VersaWorks RIP software which allows users to efficiently prepare artwork for both print & cut functions with ease. An intuitive device, the BN-20 simplifies print production and helps users easily manage output and costs by monitoring replacement of consumable parts like wipers and contour cutting blades. The BN-20 is connected via USB interface for ease of use.

Not only does the BN-20 print quality graphics up to 1440 dpi, but it cuts them as well! This means you can create labels, decals, t-shirt transfers and other products that are cut to the unique compositions of

your designs. You can also print and cut laminated graphics as part of a Quadralign® optical registration system workflow that automatically compensates for skew and distortion— remove your prints, laminate them and reload them for cutting.

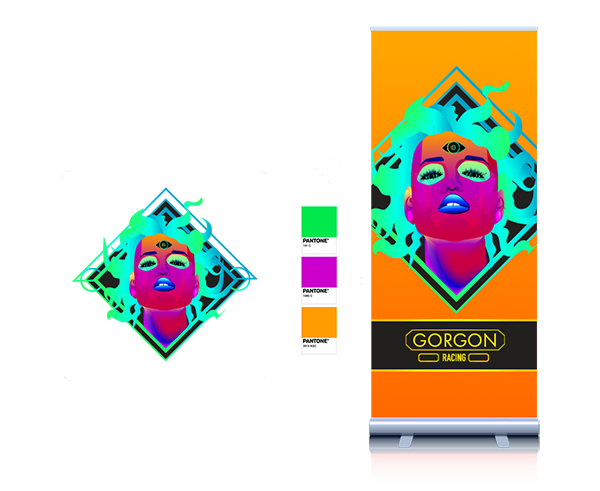

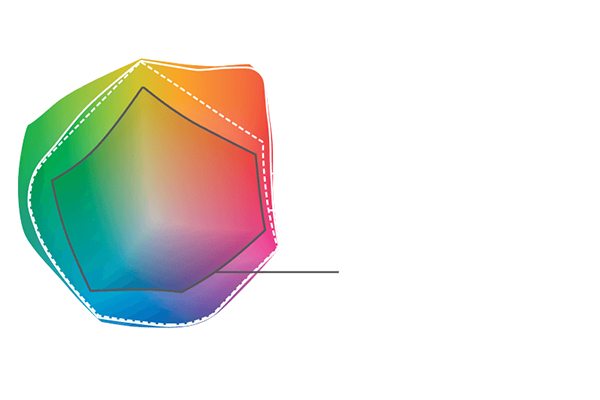

Orange and Green process color options allow you to hit specific Orange to Red areas and Blue to Green areas with approximately 260 new spot color references now available in the new Roland DG Color Library. Specific Pantone® or DIC colors that were previously difficult to match can now be easily achieved.

Reach new areas of color, including purples, reds, greens, and other challenging hues— elevating all your print output with True Rich Color 2. Improve reproduction of specific brand colors and combine

neutral grays, smooth gradations, and natural skin tones to produce color quality of incomparable realism and complexity.

| Model | VersaStudio BN-20 | |

|---|---|---|

| Printing method / Cutting method | Piezoelectric inkjet / Grit roller feed | |

| Acceptable media | Width | 5.9 to 20.3 in. (150 to 515 mm) |

| Thickness | Printing: Maximum 39 mil (1.0 mm) with liner | |

| Cutting: Maximum 16 mil (.4 mm) with liner | ||

| Roll Weight | Maximum 13.2 lbs (6 kg) | |

| Roll Outer Diamater | Maximum 5.9 in (150 mm) | |

| Core Diamater | 2 in (50.8 mm)or 3 in (76.2 mm) cores | |

| Printing/cutting width1 | Maximum 18.9 in (480 mm) | |

| Ink cartridges | Type | |

| Ink Cartridges | Type & Capacity | Roland ECO-SOL MAX or FPG Aqueous, 220 ml only |

| Colors | 5 Color – CMYK+Mt (Cyan, Magenta, Yellow, Black and Metallic Silver) or CMYK+Wh (Cyan, Magenta, Yellow, Black, and White) | |

| 4 Color - CMMYK (Cyan, Magenta, Yellow, Black) | ||

| Printing resolution | Max 1440 dpi | |

| Cutting Blade | Type | Roland CAMM-1 series cutter blade |

| Blade Offset | Fixed at 0.250 mm | |

| Cutting speed | 0.4 (10 mm/s) to 5.9 in/s (150 mm/s) | |

| Blade force | 30 to 300gf | |

| Software resolution (when cutting) | 0.000984 in/step (0.025 mm/step) | |

| Distance accuracy (when printing)2,3 | Error of less than ± 0.3 % of distance traveled, or ± 0.3mm (0.012 in), whichever is greater. | |

| Distance accuracy (when cutting)2,4 | Error of less than ± 0.4 % of distance traveled, or ± 0.3mm (0.012 in), whichever is greater. | |

| Repetition accuracy (When cutting)2,5 | ±0.004 in (± 0.1mm) or less | |

| Alignment accuracy for printing and cutting2,6 | ±0.020 in (± 0.5mm) or less | |

| Alignment accuracy for printing and cutting when reloading media2,7 | Error of less than ± 0.5% of distance traveled, or ± 0.012 in (3mm), whichever is greater | |

| Print Heater Temperature8 | Fixed at 95o F (35oC) | |

| Connectivity | USB 2.0 | |

| Power-saving function | Automatic sleep feature / AC 100 to 240V ± 10%, 1.5 A, 50/60 Hz | |

| Power Consumption | During Operation | Approx. 90 W |

| Sleep Mode | Approx. 5.5 W | |

| Acoustic Noise Level | During Operation | 62 dB (A) or less |

| During Standby | 42 dB (A) or less | |

| Dimensions/Weight | 39.2" W x 23" D x 11.5" H (995 W x 585 D x 291 H mm), 79.4 lbs (35 kg) | |

| Operating Conditions | Power on | Temperature: 68o - 90o F (20 to 32o C), humidity: 35 - 80% RH (non condensing) |

| Power off | Temperature: 41o - 104o F (5 to 40o C), humidity: 20 - 80% RH (non condensing) | |

| Included Items | Power cord, USB cable, blade, blade holder, Rolandsoftware Package9, Software RIP (VersaWorks), User's Manual, etc | |

| *1 The length of printing or cutting is subject to the limitations of the program. | ||

| *2 Using Roland specified media, loaded correctly, temperature: 25°C (77°F), humidity: 50 %RH, all pinch rollers are used, 25 mm or more for both right and left margins and 35 mm or more front margin, excluding expansion or contraction of the emdia, and all correction and adjustment functions of this machine have been made properly. | ||

| *3 Using Roland specified media, print travel of 1m. | ||

| *4 Using Roland specified media, cut travel of 1m. | ||

| *5 Range for assured repetition accuracy: Length 1,000 mm. | ||

| *6 Provided that media length is under 1,000 mm. Excluding possible shift caused by expansion/contraction of the media and/or by reloading the media. | ||

| *7 Using Roland specified media, data size: 1,000 mm in the media-feed direction, 480 mm in the carriage-movement direction. No lamination. Automatic detection of crop marks at 4 points when media is reloaded. Excludes the effects of skewed movement and of expansion and contraction of the media. | ||

| *8 Warm-up is required after power up. This may require 5 to 20 minutes, depending on the operating environment. The preset temperature may fail to be reached 35°C (95°F) depending on the ambient temperature and media width. | ||

| *9 Roland Software Package includes: Windows driver, OnSupport software, utility software and R-Works design software | ||

#1: Getting Started

#2: Out of the Box

#3: Drivers & Software

#4: Installing Ink

#5: Installing the Blade

#6: Loading the Media

#7: Calibration

#8: Maintenance

#9: Daily Maintenance

#10: Periodic Maintenance

#11: Utility Software

#12: Periodic Maintenance

#13: Waste Ink Cartridge

#14: Replacing the Wiper

#15: Replacing the Cutter Blade

#16: Versaworks Software

#17: Nesting Print Jobs

#18: Contour Cutting

#19: Cut Paths in Corel Draw

#20: Print & Cut Separately

#20: Print & Cut Separately

#21: Metallics in Illustrator

#22: Printing Metallics

#23: Printing From Corel Draw

#24: Printing From Illustrator

Replacing the Felt Wiper

Replacing the Cutter Strip

Color Matching for Beginners

Print & Cut for Beginners

BN-20 Tips and Tricks (1:44)

BN-20 Tutorial

BN-20 Queue Settings

BN-20 Optimal Print Quality

BN-20 Profile Center

BN-20 Importing Profiles